Publiesse made its first screen print in 1976. With 50 years of experience, new technologies and advanced machinery have been introduced. Shiny, matte, fluorescent, gradient effects…it’s a never-ending story of incomparable quality.

MANUFACTURING

Teamwork guides every step of our process, from leather cutting to final quality control.

Our expertise lies in combining different technologies to create products that are constantly reinvented.

Screen Printing

Embossing 3D

Thanks to this technique, leather keeps its appearance even as its visual structure changes. Using special moulds, we create ultra high-definition three-dimensional effects with a remarkably realistic relief.

High Frequency

HF allows materials to take on new appearances, generating volumes, intricate micro and macro textures, puffy effects, and subtly debossed surfaces. Custom-made moulds make each project truly unique, with unmatched attention to detail and texture.

D3/D5/Texflex

Mixing heat sealing and thermoforming, HF creates special treatments using patented techniques, giving the surfaces a unique feel and extraordinary effects. Material finishes and colors come in endless combinations: metallic, frost, glossy, transparent, glittered.

Digital Printing

Inkjet printing allows every single color to be reproduced with a photographic effect on leather, synthetics, and fabrics. Endless possibilities in terms of color range and gradient effects.

Embroidery

If you are looking for added value for your products, embroidery is the solution. We manage the project in its entirety, combining different savoir-faire, and offer thousands of materials to apply, such as pearls, sequins, studs… making each project truly unique.

Laser & Color

High technology laser cutting with colours addition, with the best grip you can imagine. We transform even the simplest laser cut into a rich, distinctive surface.

Tape & Film Application

Playing with tapes creates new effects and improves the performances. Combining it with other technologies produces thousands of variants.

Rubber & Micro Injection

Ideal for giving products a distinctive rubbery touch. The technology allows the creation of items and inserts in TPU and PVC rubber, in single or multicolor, with the possibility of injecting rubber directly through leather for a perfect bond and finish.

Final Finishing

Designed to enhance and protect prints, this technology allows the application of protective top coats that safeguard surfaces, preserving their quality, texture, and vibrancy.

Cutting & Micro Perforations

By cutting whole hides and a variety of materials, we streamline the production process, enabling us to provide our clients with an ever more complete and high-quality service. We can perform micro-perforations and prepare the necessary supports and materials for the realization of each product.

Our expertise lies in combining different technologies to create products that are constantly reinvented.

Screen Printing

Publiesse made its first screen print in 1976. With 50 years of experience, new technologies and advanced machinery have been introduced. Shiny, matte, fluorescent, gradient effects…it’s a never-ending story of incomparable quality.

Embossing 3D

Thanks to this technique, leather keeps its appearance even as its visual structure changes. Using special moulds, we create ultra high-definition three-dimensional effects with a remarkably realistic relief.

High Frequency

HF allows materials to take on new appearances, generating volumes, intricate micro and macro textures, puffy effects, and subtly debossed surfaces. Custom-made moulds make each project truly unique, with unmatched attention to detail and texture.

D3/D5/Texflex

Mixing heat sealing and thermoforming, HF creates special treatments using patented techniques, giving the surfaces a unique feel and extraordinary effects. Material finishes and colors come in endless combinations: metallic, frost, glossy, transparent, glittered.

Digital Printing

Inkjet printing allows every single color to be reproduced with a photographic effect on leather, synthetics, and fabrics. Endless possibilities in terms of color range and gradient effects.

Embroidery

If you are looking for added value for your products, embroidery is the solution. We manage the project in its entirety, combining different savoir-faire, and offer thousands of materials to apply, such as pearls, sequins, studs… making each project truly unique.

Laser & Color

High technology laser cutting with colours addition, with the best grip you can imagine. We transform even the simplest laser cut into a rich, distinctive surface.

Tape & Film Application

Playing with tapes creates new effects and improves the performances. Combining it with other technologies produces thousands of variants.

Rubber & Micro Injection

Ideal for giving products a distinctive rubbery touch. The technology allows the creation of items and inserts in TPU and PVC rubber, in single or multicolor, with the possibility of injecting rubber directly through leather for a perfect bond and finish.

Final Finishing

Designed to enhance and protect prints, this technology allows the application of protective top coats that safeguard surfaces, preserving their quality, texture, and vibrancy.

Cutting & Micro Perforations

By cutting whole hides and a variety of materials, we streamline the production process, enabling us to provide our clients with an ever more complete and high-quality service. We can perform micro-perforations and prepare the necessary supports and materials for the realization of each product.

Discover all the pb76 stories

Make it happen

Fashion Racing

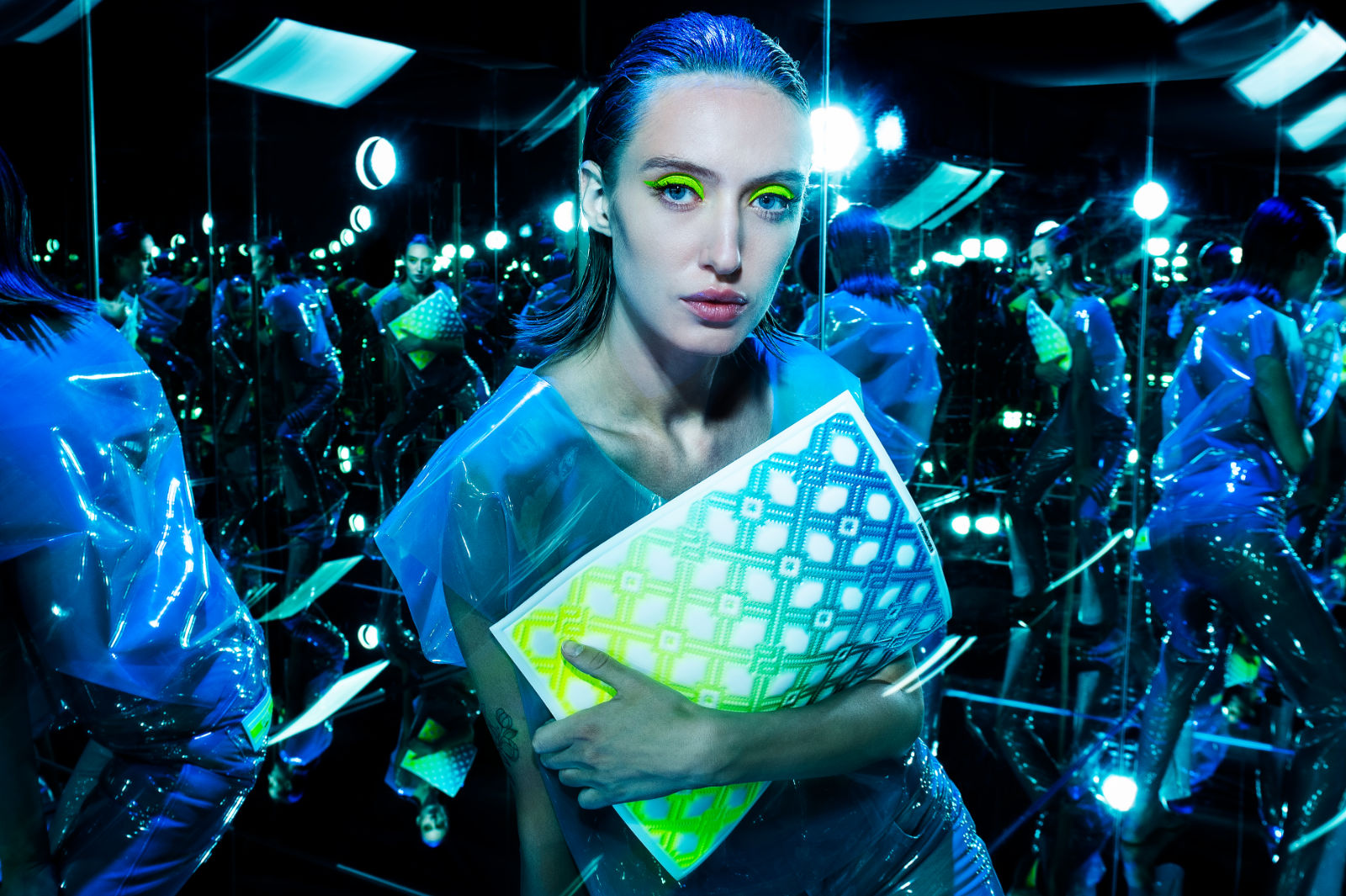

Beams of Light

The Tarot

The Motel

The Dollhouse